The Role of the Regulating wheel and The Work Rest Blade in Centerless Grinding

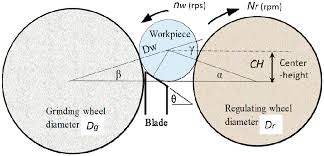

Centerless Grinding consist of grinding cylindrical workpieces without centers. The workpiece revolves between two wheels. One wheel is called the regulating wheel the other is the grinding wheel. The grinding wheel generally travels at a fixed RPM and the regulating wheel travels at a selected slower speed to control the rate of spin of the of the part.

The regulating wheel is most often made of hard rubber and abrasive and its role is instrumental in moving the part being ground through the grinder by either a Through-feed or In-feed process.

? Through-feed - The regulating wheel angle of inclination typically is in the +1 degree to +3-degree range. This angle, along with regulating wheel speed (RPMs ranging from 15 to 300 RPM), determines the part thru-feed rate in inches per minute. The speed of the RPM is dictated by the part size and length. Too fast of an RPM can result in Chatter. If the angle of the regulating wheel is too acute, it can cause uneven wear, taper, and poor wheel life. If the regulating wheel is too close to parallel with the grinding wheel, it can cause the parts to stall between the wheels.

? In-feed - Infeed centerless grinding is similar to plunge grinding on a center-type machine and is often used to grind workpieces with relatively complex shapes. The workpiece rest blade needs to be tooled to match the shape of the part and the grinding and regulating wheels must be dressed to match the part�s desired profile cut. The regulating wheel is fed into the part pushing it against the grinding wheel. The work does not move axially as it does in through feed grinding.

The Work Rest Blade - The role of the work rest blade is to keep the part in contact with the regulating wheel.

Most often the centers of the regulating and grinding wheels are set at the same height on a centerless machine, and the center of the workpiece is situated higher sitting on the work rest blade. The height of the work rest blade is important, as an example if the workpiece is set too high, it can cause chatter; if the workpiece is set too low, it may be out of round.

The top of the work rest blade generally has an angle of 30-degrees but can range from 0 to 45 degrees. The angle slopes towards the regulating wheel which in turn drives the part. The angle of the workpiece rest blade is also critical to centerless grinding. A narrow wheel that is three to four inches wide may work well at 30� but a wider wheel at 6� to 10� may generate too much pressure toward the grinding wheel causing chatter and may require an angle of 20� to 25�.

The Centerless Grinder is an extremely versatile machine and the Regulating wheel and Work Rest blade are instrumental in its successful operation.

�